Plastic injection molding is the most basic and important process in the plastic products industry. Plastic injection molding can be used in a wide range of applications, for example, household appliance shells, auto parts, beauty equipment, medical equipment, and electronics products need to use injection molding technology. Good plastic molded parts are inseparable from good injection molding molds.

Then how to make a plastic injection molding mold?

The plastic injection mold production process is generally divided into the following 5 steps: mold design, mold manufacturing, mold inspection and mold trial, mold modification and mold maintenance, mold maintenance. Do these 5 steps step by step and control the quality well, a good plastic injection molding mold can be made overnight.

1. Strictly review all documents customized by customers. Before opening the plastic injection molding mold, our engineers conduct a comprehensive inspection in 2D and 3D to understand the customer’s requirements for the use, material, size, structure, color, and product tolerance of the plastic injection molding

2. Engineers design customized plastic injection molding molds through professional drawing tools according to requirements. In this step, the length of the molding runner, mold line position, mold temperature, ejector pin position, etc. is strictly controlled. Fully consider the screw, mold cooling and thimble device: the arrangement should pay attention to the influence of the screw and thimble on the mold cooling water pipe. Finally, the drawing of the plastic injection molding mold is completed.

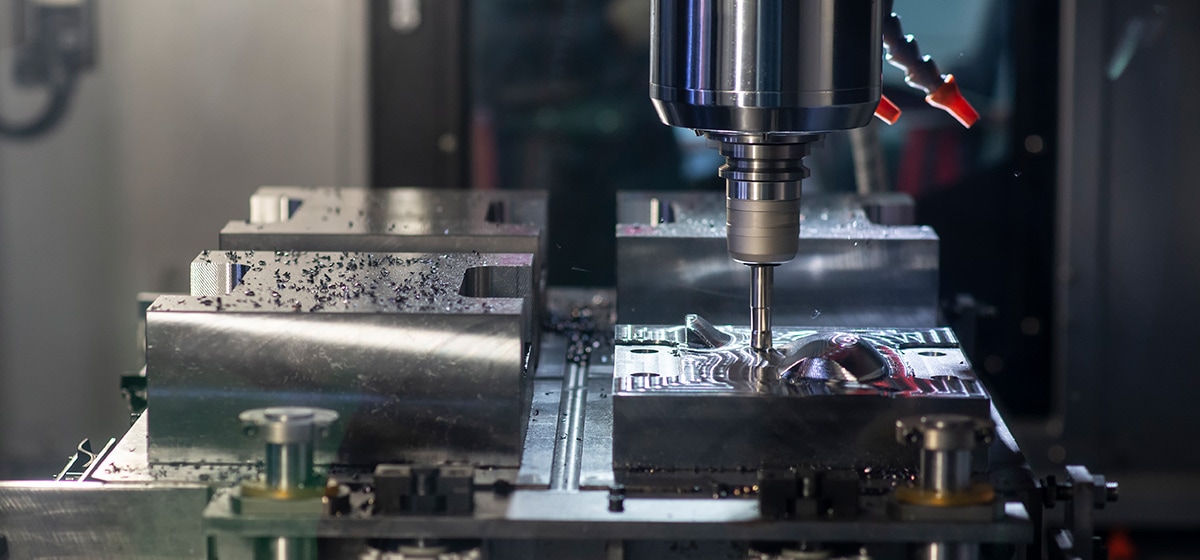

3. Plastic injection molding mold manufacturing plays a vital role. This step determines whether a good Plastic injection molding mold is made. CNC and EDM processing must be used according to the processing requirements of each part to ensure quality and hardness. Fitter assembly is carried out after the mold parts are made, and the fitter runs through the entire mold manufacturing process. Molds are finished with assembly attention to detail and precision.

4. Plastic injection molding molds need strict inspection and multiple trial molds. It needs to be put on the injection machine for mold trial in order to check the condition of the mold after the mold is manufactured. Through the mold test, you can know whether the data of the mold meet the customer’s requirements or not. If not, a second mold trial must be carried out until the customer’s requirements are met.

5. Plastic injection molding molds need maintenance. It is easy to rust due to the molds working under high temperatures and high pressure, and it is in contact with air for a long time. Therefore, it is necessary to maintain the mold well. Applying butter is the most direct and most effective. It is convenient for us to use plastic injection molding mold again. We are a plastic injection mold manufacturer, focusing on providing customers with a complete set of solutions from product design, mold manufacturing, injection molding , assembly, and after-sales service. Products are widely used in electronic product shells, household products, medical plastic injection molding parts, cosmetic instruments and other fields. Welcome to inquire.